The use of Liquid Silicone Rubber (LSR) equipment has been steadily increasing in various industries due to its unique properties and advantages. lsr equipment is specifically designed for the processing of liquid silicone rubber, which offers excellent durability, flexibility, and heat resistance. In this article, we will explore the industry trends related to lsr equipment with a focus on its durability and cost factors.

Durability of LSR Equipment

LSR equipment is known for its exceptional durability, making it suitable for long-term usage in demanding applications. The materials used in the construction of LSR equipment are resistant to wear and tear caused by continuous operation and exposure to high temperatures. This ensures that the equipment can withstand rigorous production processes without compromising performance or efficiency.

In addition, the design of LSR equipment incorporates features such as corrosion-resistant components and robust structures that further enhance their durability. These characteristics make them ideal for industries where reliability is crucial, such as automotive manufacturing, medical device production, and consumer goods fabrication.

Cost Considerations with LSR Equipment

While initial investment costs may be higher compared to traditional molding methods, using LSR equipment can result in significant cost savings over time. The durable nature of LSR molds reduces maintenance requirements and extends their lifespan compared to other types of molds.

Furthermore, the precise control offered by modern LSR injection molding machines minimizes material waste during production. This not only reduces raw material costs but also contributes to environmental sustainability efforts within industries utilizing these machines.

In terms of operational costs, advanced automation capabilities integrated into many modern LSR systems improve overall efficiency while reducing labor expenses associated with manual handling tasks. Additionally, shorter cycle times achieved through optimized process parameters lead to increased productivity and reduced energy consumption.

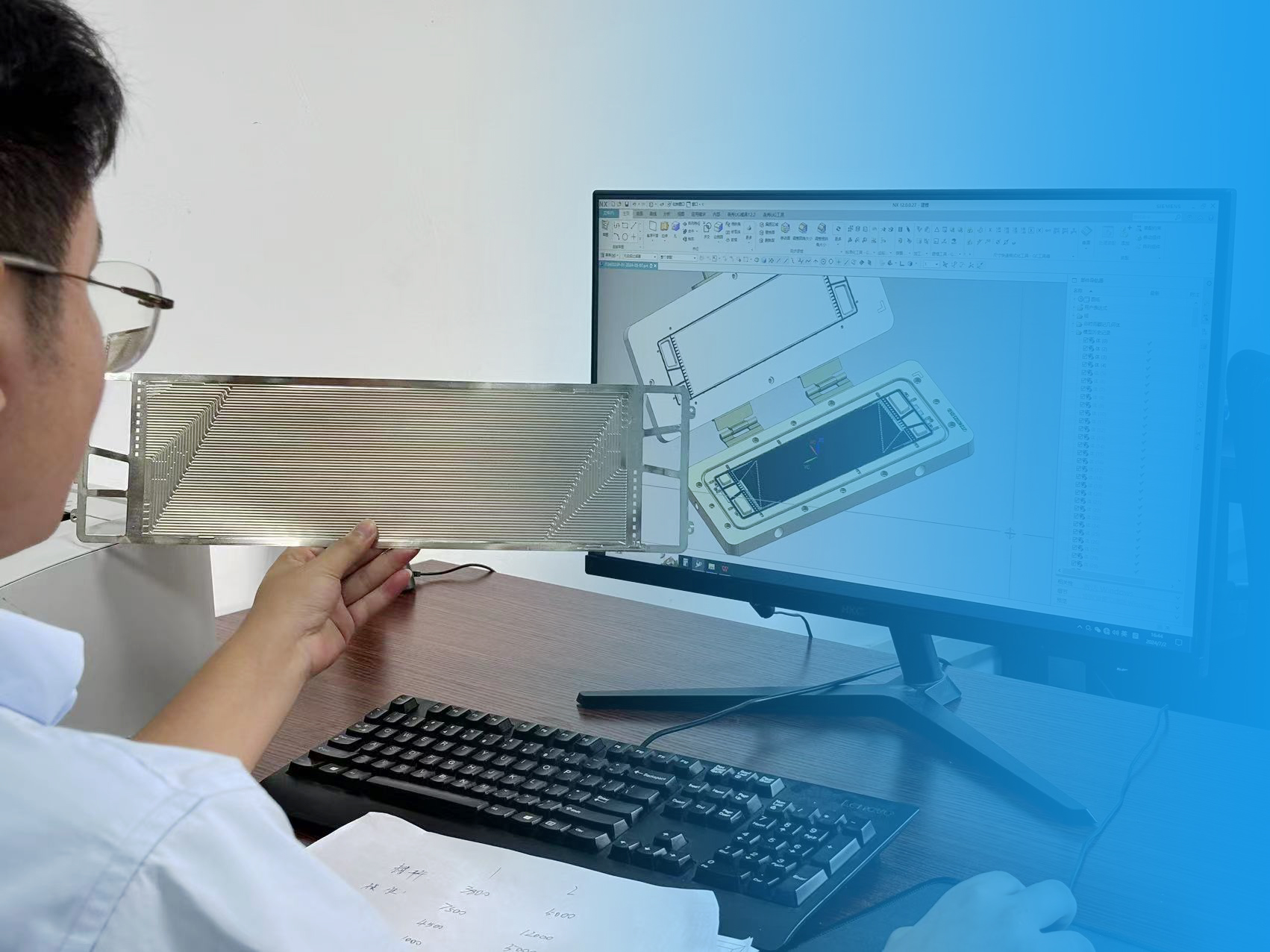

JVTECH: A Leader in LSR Equipment

When it comes to reliable and high-quality LSR equipment, JVTECH stands out as a leading manufacturer. With years of experience in the industry, JVTECH offers state-of-the-art LSR injection molding machines that are known for their durability, precision, and cost-effectiveness.

Their advanced technology ensures consistent production results with minimal variation, meeting the stringent requirements of various industries. Moreover, JVTECH provides comprehensive technical support and maintenance services to ensure optimal performance throughout the lifespan of their equipment.

The Role of LSR Equipment in Toy Molding

In toy manufacturing, LSR equipment plays a vital role due to its ability to produce intricate designs with excellent detail reproduction. The flexibility of liquid silicone rubber allows for complex shapes and textures that enhance the visual appeal and functionality of toys.

Furthermore, the durability aspect is crucial in toy molding as it ensures that toys can withstand rough play without easily breaking or deforming. This not only enhances customer satisfaction but also reduces costs associated with product returns or replacements.

LSR equipment enables efficient production processes by offering fast cycle times and automated features that streamline toy manufacturing operations. These advantages make it an ideal choice for companies looking to optimize both quality and cost-efficiency in this competitive market segment.

Conclusion

In conclusion, the increasing adoption of LSR equipment across various industries is driven by its exceptional durability combined with cost-saving benefits. The durable nature of these machines ensures long-term reliability while minimizing maintenance requirements. Additionally, optimized process parameters reduce material waste and improve overall efficiency, resulting in significant cost savings over time.

JVTECH emerges as a prominent player in providing reliable LSR equipment solutions backed by their expertise and comprehensive support services. In toy molding, LSR equipment offers the ability to create intricate designs with durability, enhancing both customer satisfaction and cost-effectiveness.

As industries continue to seek advanced manufacturing solutions, LSR equipment remains a key player in meeting the demands for durable and cost-efficient production processes.